Galvanization in “Orao” – More Than Fifteen Processes, Some Unique in Europe and the World

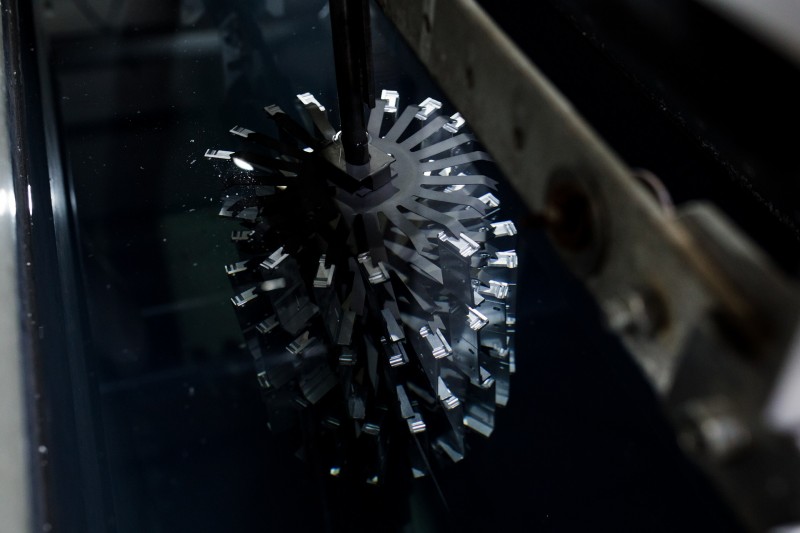

The company “Orao” a.d. has been performing complex electrochemical surface protection processes for thirteen years in a modern facility opened in 2012, built according to high technological standards. Within its seven mechanized production lines, more than fifteen processes are carried out daily — some of which are unique on the European and global level.

The Head of the Electrochemical Protection Department at “Orao”, Dubravka Banjac, explains that the modern facility performs, among other things, processes ranging from anodic oxidation and chromating of aluminum to hard chrome plating and silver plating.

“The company ‘Orao’ is primarily engaged in aircraft engine overhauls, where the repair of certain parts is allowed. One of the special processes used in part repair is electrochemical protection. As I mentioned, these include anodic oxidation (anodizing) of aluminum and aluminum alloys, chromating of aluminum and magnesium, nickel plating, silver plating, as well as copper plating, cadmium plating, zinc plating, phosphating, bluing, hard chrome plating, lead plating, and indium plating,” explains Banjac.

She emphasizes that galvanization is a process of applying protective coatings with anti-corrosive, anti-wear, and anti-friction properties.

“Galvanization at ‘Orao’ a.d. Bijeljina is specific because we have all the necessary processes for the overhaul of turbojet aircraft engines in one place. Furthermore, some processes based on hexavalent chromium or cadmium, whose use will be banned in Europe from January 2025 in the civil sector, are still present in aviation, and we use them in the repair process. In the past year, the demand for these processes has increased among clients across Europe. Our department currently employs eleven people — three engineers and eight technicians — mostly from the fields of mechanical and chemical engineering,” notes Banjac.

Several electrochemical processes, such as anodic oxidation in chromic acid, aluminum chromating, cadmium plating, and hard chrome plating, are approved by world-renowned aerospace companies — Pratt & Whitney (Canada), Collins Aerospace (USA), and General Electric (USA). In addition, “Orao” is an approved subcontractor for electrochemical processes according to Boeing’s standards, whose engines are serviced by “JAT Tehnika” in Belgrade and used in the Air Serbia fleet.

“Most of our processes are performed according to Rolls-Royce standards, but thanks to external clients — both from the aviation and civil sectors — we continuously adapt and adopt new standards to meet their needs, such as those from the energy and automotive industries. For example, we carried out the chrome plating of the landing gear strut for a civil Boeing 737 aircraft for ‘JAT Tehnika’, and they come every year to inspect and verify that we work according to their standards. For ‘Pratt & Whitney’, our production manufactures certain parts, as does the company ‘Unimet’ from Kać, whose parts we protect electrochemically — and only ‘Orao’ is certified for the anodic oxidation in chromic acid process,” says Banjac.

The Director of “Orao” a.d. Bijeljina, Marko Mrkajić, emphasizes that thanks to the company’s laboratory and research & development department, “Orao” is capable of mastering any new technology and adapting to the increasingly demanding global market.

“We have the capability to perform all testing, verify processes, and prove compliance with the requirements of major global companies. The team working in the Electrochemical Protection Department has recently undergone a generational shift, with younger operators, technologists, and engineers now having the opportunity to learn extensively from experienced supervisors. I would also emphasize that the galvanization facility is equipped with a modern system for wastewater and air purification, thus fully meeting environmental and occupational safety regulations,” adds Mrkajić.

The component repair facility, where electrochemical protection processes are carried out, was opened in 2012 within the premises of “Orao” a.d. Bijeljina. It represents a capital investment of national significance, unique in Bosnia and Herzegovina and the region. The facility includes areas for part preparation, galvanization, quality control, wastewater and air treatment, and solid and liquid waste storage.

Thanks to the large number of electrochemical protection processes “Orao” performs, an increasing number of civil industry companies from Bosnia and Herzegovina, Serbia, and the region are reaching out for specialized services. Particularly in demand are anodic oxidation of aluminum alloys, silver plating, hard chrome plating, cadmium plating, bluing, and phosphating.

The electrochemical plant demonstrates that investment in a modern facility — whose construction lasted one year — was indeed the right move for “Orao”. It has brought together state-of-the-art processes needed by both the aviation and civil industries, and through knowledge, experience, and dedication, has opened doors to new business opportunities and employment.